Why Choose Pallet Racking in Auckland Warehouses?

Warehouses and distribution centres in Auckland face tight space constraints, growing demand, and increasingly stringent safety and compliance requirements. One foundational solution that helps address all these challenges is the right pallet racking system. But what makes pallet racking such a smart choice? Here’s a detailed look at the benefits, considerations, and how Dexion Auckland helps you get it right.

What Is Pallet Racking?

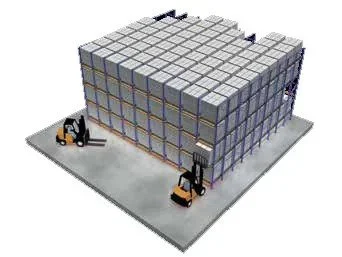

Pallet racking is a storage system in which materials are stored on pallets (or “skids”), placed on steel frameworks (uprights and beams), often in multiple levels. Forklifts place and retrieve the pallets. Different styles exist (selective, double-deep, drive-in, drive-through, etc.), each with trade-offs between accessibility, density, cost, and handling speed.

Narrow Aisle Racking | Double Deep Racking | Push Back Racking | Drive-In Racking | Selective Pallet Racking

Key Benefits of Pallet Racking

Here are the main reasons many Auckland warehouses choose pallet racking solutions:

1. Optimised Use of Space (Vertical & Floor)

Warehouses often have high ceilings; pallet racking allows use of vertical space, stacking pallets up many levels rather than spreading out laterally. This reduces the warehouse footprint needed for a given volume of goods.

Different racking types (e.g. very narrow aisle, double depth, drive-in) help reduce aisle space and increase storage density.

2. Improved Inventory Access & Efficiency

The right racking layout reduces the travel time for forklifts and staff getting to pallets, which speeds up order fulfilment.

It enables more organised storage of SKUs, which helps with workflow, stock rotation (e.g. FIFO / LIFO), and reduces picking errors.

3. Safety & Compliance

Pallet racking keeps goods off the floor, safely supported, reducing damage or risk of collapse. Proper design, installation, and maintenance reduce workplace hazards.

In NZ & Australasia, Dexion ensures its racking meets AS4084 standard (steel storage racking standard) including new updates.

WorkSafe guidance in NZ emphasises selecting and maintaining racking systems carefully.

4. Flexibility & Scalability

Modular racking systems let you reconfigure or expand as your storage needs change: adding more levels, extending bays, adjusting beam heights, converting to different racking types.

Different styles of racking allow a business to choose trade-offs: maximum density vs full selectivity vs cost. E.g. selective racking offers direct access to each pallet; compact/deep systems provide more storage but have trade-offs in access time.

5. Cost Efficiency & Return on Investment

While the upfront cost of installing robust pallet racking is significant, savings come from better space usage (which may avoid need to expand premises), reduced damage to goods, improved throughput, lower labour costs.

Longevity: good quality racking, properly maintained, can last many years, making the investment pay off over time.

Considerations for Auckland Warehouses

When selecting or upgrading pallet racking in Auckland (or NZ generally), keep these in mind to get the full benefit:

Compliance with AS4084:2023 (or relevant current standard) for design, installation, maintenance, audits.

Floor strength, building height, roof loading, seismic risk (NZ is seismically active). The structure must accommodate upright loads, beam loads, lateral forces.

Material handling equipment compatibility: Forklift reach height, aisle width, clearances, loading/unloading access.

Inventory flow method: Whether you need FIFO (first in first out) or LIFO, or mixed. This influences racking type and layout.

Maintenance and inspection program: Regular checks, prompt repair of damage, load rating clear labelling. WorkSafe recommends good practice for selection, use and maintenance of pallet racking systems.

How Dexion Auckland Helps You Get It Right

Here’s how partnering with Dexion Auckland ensures you make the best choice:

We design pallet racking systems that comply with AS4084 standards to ensure safety and durability.

We provide engineering-backed layouts to match your warehouse floor plan, inventory turnover, forklift fleet, temperature / environment etc.

Our modular components allow for incremental expansion—so you don’t need to overcapitalise up front.

We inspect and maintain racking, offering safety checks to keep systems compliant and safe.

We can advise on the best type of pallet racking for your needs: whether selective, double-deep, drive-in or other systems, balancing between access speed and density.

Is Pallet Racking the Right Choice for Your Operation?

You should consider pallet racking if:

You store large volumes of palletised goods.

Your floor space is limited, but the warehouse has height you can leverage.

You need safe, reliable, and compliant storage over many years.

You need a layout that supports efficient workflows, fast order picking, minimal waste/damage.

You're planning for growth and want flexibility in your infrastructure.

Pallet racking remains one of the most effective, versatile, and proven solutions for warehouse storage in Auckland. When well designed and maintained, it maximises your space, improves operations, ensures safety, and delivers strong ROI. For many businesses, the question isn’t if but how soon they should upgrade or install an optimal racking system.